Description

Commonly known as Nylon this is an extensive group of thermoplastics with a broad range of properties. They take the form of fibre, film and moulding compounds and offer good chemical and heat resistance and have high wear and low friction characteristics. Polyamides are processed by extrusion, injection moulding, rotational moulding and casting.

History

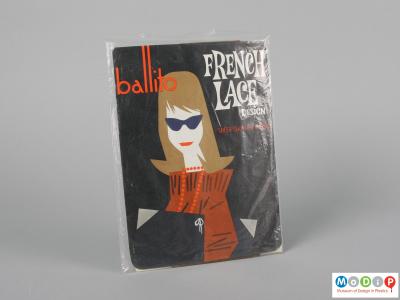

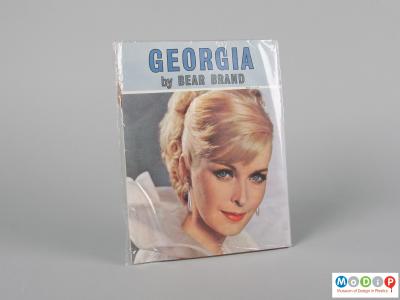

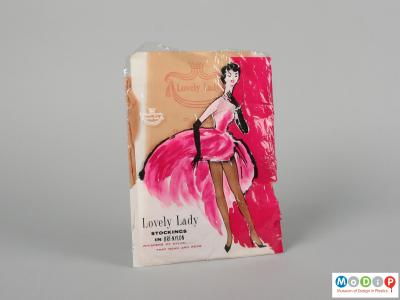

Developed in the early 1930s by DuPont research scientists Julian W. Hill and Wallace H. Carothers, the first commercial uses of polyamide fibres were as toothbrush bristles, nylon stockings and parachute fabric. Nylon moulding powders combined with reinforcement fillers, such as glass, were subsequently developed and were widely used from the 1950s onwards.

Common uses

The wide range of properties of polyamides has resulted in an extensive range of applications. It is commonly used as textile fibres in clothing, carpets and leisure wear and equipment, ropes and nets and Velcro. As a thicker monofilament, it is used as toothbrush tufts, utility brushes and strings for musical instruments. In a more rigid form, exploiting its resistance to high temperatures and good stability under heat, it is used domestically for kitchen utensils, in engineering applications and widely in the automotive industry.

Recyclability

Rigid form polyamides can be reground to pellet size and reprocessed. Fibrous polyamides are also recycled using a range of processes which extract the polyamide rendering it suitable for re-use with minimum loss of performance.