Decarbonisation is a theme in our current exhibition, Reuse.

Carbon footprints are a measure of the amount of carbon dioxide and other greenhouse gases released over the full life cycle of a product. They are notoriously difficult to assess because there are many factors that need to be considered. For example, extraction and processing of the raw materials, manufacturing, packaging and transportation of the product, useage (how long it is used for and whether it is reused) and then finally, recycling and disposal at end-of-life.

The environmental impacts associated with plastics are often generally much lower than that of alternative materials such as glass, metal and paper. However, there are several ways by which they can be further decarbonised. Incorporating recycled content, selecting biopolymers instead of plastics derived from fossil fuels or using carbon neutral materials are some potential transformational solutions.

All of these objects

are sourced

from plant-based materials rather than fossil fuels.

All of these objects

are sourced

from plant-based materials rather than fossil fuels.

Image credit: MoDiP

In the drive towards becoming net zero, businesses involved with plastics can also try to make efficiencies across their general operations, production processes and supply chains. They might consider switching to low-carbon technologies, using renewable energy sources, adopting closed-loop systems to minimise waste and choosing partners who also prioritise decarbonisation. When areas of unavoidable impact still exist, they might invest in guaranteed carbon offsetting projects, designed to reduce future emissions.

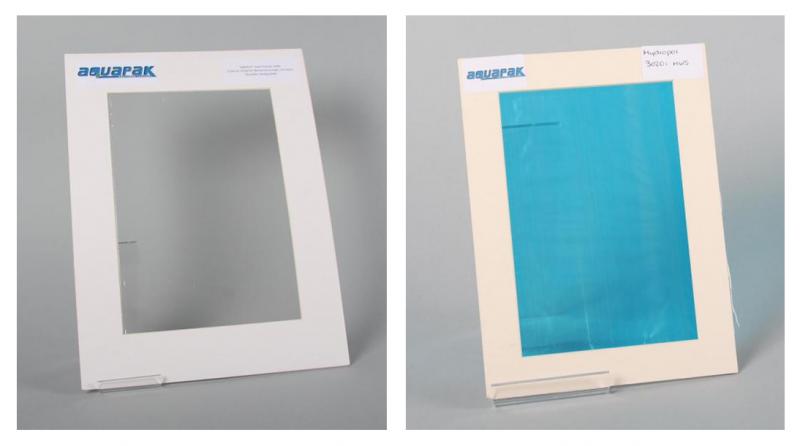

Examples of carbon

neutral materials.

Examples of carbon

neutral materials.

Image credit: MoDiP

Katherine Pell

Collections Officer

Carbon footprints are a measure of the amount of carbon dioxide and other greenhouse gases released over the full life cycle of a product. They are notoriously difficult to assess because there are many factors that need to be considered. For example, extraction and processing of the raw materials, manufacturing, packaging and transportation of the product, useage (how long it is used for and whether it is reused) and then finally, recycling and disposal at end-of-life.

Image

This

wine bottle is made from 100% recycled PET

from

Prevented Ocean Plastic (POP).

Image credit: MoDiP

The environmental impacts associated with plastics are often generally much lower than that of alternative materials such as glass, metal and paper. However, there are several ways by which they can be further decarbonised. Incorporating recycled content, selecting biopolymers instead of plastics derived from fossil fuels or using carbon neutral materials are some potential transformational solutions.

Image

Image credit: MoDiP

In the drive towards becoming net zero, businesses involved with plastics can also try to make efficiencies across their general operations, production processes and supply chains. They might consider switching to low-carbon technologies, using renewable energy sources, adopting closed-loop systems to minimise waste and choosing partners who also prioritise decarbonisation. When areas of unavoidable impact still exist, they might invest in guaranteed carbon offsetting projects, designed to reduce future emissions.

Image

Image credit: MoDiP

Katherine Pell

Collections Officer