Currently the most widely accepted solution to an environmentally friendly lifecycle for single use plastic products is recycling.

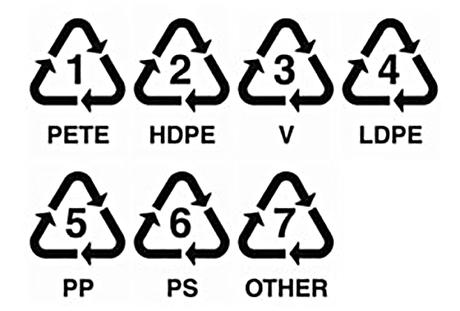

Recycling triangles

Products are manufactured with recycling triangles, which indicate that the material is capable of being recycled.

As different plastics have different physical characteristics and cannot be satisfactorily recycled together, the number identifies the particular plastic.

Issues relating to recycling

There are two issues relating to manufacturing with recycled plastics:

- Recycled plastics are not generally used again to make the same product and a proportion of virgin plastics is required.

- Recycling plastics waste also uses energy. It is only a more eco-friendly solution if the lifecycle of the product uses less energy than a product made with virgin material.

Recycling worldwide is a lottery. Whether or not plastics waste can be recycled depends on the facilities available. In the UK, polyethylene terephthalate (PET), high density polyethylene (HDPE) and polyvinyl chloride (PVC) are more widely recycled than low density polyethylene (LDPE), polypropylene (PP) and polystyrene (PS) because there is little demand for the second group and therefore little resale value. Globally only 10% of the 300 milion tonnes of plastics produced annually is recycled. With 80% of the plastics litter in the oceans originating on land, the world needs to take action.

An insurance policy

Most conventional plastics are made from fossil fuels. Oxo-biodegradable plastics, being fossil fuel based plastics, can be recycled with these conventional plastics. Manufacturing with oxo-biodegradable plastics ensures that, even if these products are not disposed of responsibly, they will biodegrade and not be a blight on the landscape or a death threat to marine life. Oxo-biodegradable plastics are not the only solution but they provide an insurance policy.