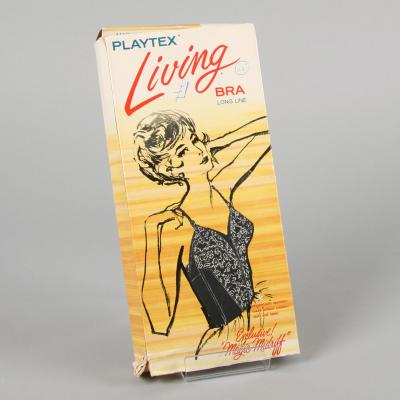

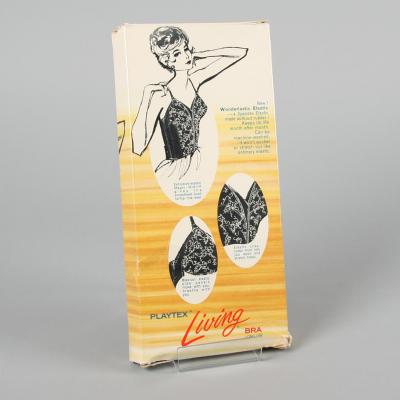

Playtex Living Bra of knitted polyester, nylon, elastane and woven cotton

Object number: MoDiP: AIBDC 000255

Designer/Maker/Manufacturer/ Retailer: Playtex (manufacturer)

Production country of the garment and components: Unknown

Production date: Probably 1960–70

Description: A black Playtex Living Bra, Style no. 1261, Size 40b, with ‘crisscross’ front, bias-cut side panels, a long back line to hip and a double row of 7 metal hook and eye fasteners. Playtex introduced the Living Bra in the late 1940s, but this example includes elastane, not made in commercial quantities until 1959, thus it cannot date to before then. There are four sections of side boning, probably nylon, with cotton lining and V-shaped panels at the front. The straps are only elasticated at the point at which they join the bra. Side locks, probably also of nylon, connect the straps to the top of the bra cups. Complete with original illustrated box, stating that it includes Spandex Elastic made without rubber.

Context: Playtex was created in 1947, the name a fusion of the words, ‘play’ and ‘latex’. In 1955, the year commercial television was introduced in Britain, it was the first brand to mention lingerie in a television commercial. Elastane has the potential to stretch and then return to its original shape. Also known by tradenames Spandex and Lycra, it has transformed the construction of under garments and is a material widely used in fashion where a degree of permanent elasticity is required.

Labels/ Inscriptions: Printed on a woven label sewn into a side seam: Playtex® STYLE 1261 SIZE 40B

Methods:

- Fibre manufacture: Farmed (cotton); extruded (polyester; nylon; elastane)

- Yarn manufacture: Staple, spun

- Fabric construction: Woven (cotton); knitted (polyester; nylon; elastane)

- Garment Construction: Stitched

Material: Polyester (main fabric); nylon (lace effect); elastane; cotton (lining and straps)

Measurements: Under bust: 73cm

Source: Gift

More information on this object: https://www.modip.ac.uk/artefact/aibdc-000255

A pair of Brettles knickers of knitted Bri-nylon™, a nylon and wool blend

Object number: MoDiP: AIBDC 008797

Designer/Maker/Manufacturer/ Retailer: Brettles (manufacturer)

Production country of the garment and components: UK

Production date: 1960s

Description: A pair of cream women's long leg, high waisted knickers made by Brettles of circular, pointelle pattern, knitted construction with inset gusset.

Context: The Brettles of Belper company dates to the early nineteenth century and is said to have supplied silk stockings to Queen Victoria (1819–1901). The company has since been owned by Courtaulds, Chilprufe and Slenderella. Both wool and nylon are moisture-wicking and dry quickly, although nylon dries faster than wool. Wool tends to be itchy which is mediated by the nylon content. Nylon is harder wearing than wool thus extending the garment’s life. The sewn-on paper price label indicates that it was originally sold for 12/11 (twelve shillings and eleven pence), a relatively high price.

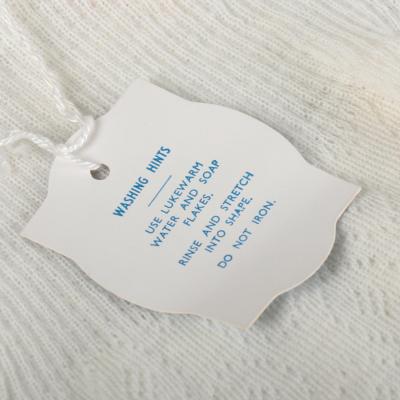

Labels/ Inscriptions: Printed on swing tag attached to waist: Brettles WOOL and BRI-NYLON MADE IN ENGLAND WASHING HINTS - USE LUKEWARM WATER AND SOAP FLAKES. RINSE AND STRETCH INTO SHAPE. DO NOT IRON.

Woven label sewn into waist: Brettles WOOL & BRI-NYLON MADE IN ENGLAND. W

Handwritten paper tag sewn to waist: SB 1064 RG/- Grace W 12/11

Methods:

- Fibre manufacture: Farmed (wool); extruded (nylon)

- Yarn manufacture: Staple, spun

- Fabric construction: Knitted

- Garment Construction: Stitched

Material: Nylon (Trade name: Bri-nylon) and wool blend

Measurements: Length 54cm

Source: Purchase

More information on this object: https://www.modip.ac.uk/artefact/aibdc-008797

Alexandre Ltd. man's suit of woven nylon lined with Milium, a blend of viscose rayon and metal thread

Object number: Leeds Museums and Galleries: LEEAG.2012.0285

Designer/Maker/Manufacturer/ Retailer: Alexandre Ltd. (designer and manufacturer)

Production country of the garment and components: UK

Production date: 1960–70

Description: Jacket from a man’s two-piece suit of blue-grey twill with white pinstripe. Jacket fastens with 3 grey buttons; narrows at waist; two side pockets with flaps; one external breast pocket; one internal breast pocket with button. Both warp and weft threads from this garment were found to be nylon by FTIR analysis. The use of these relatively new synthetic fibres was a fashion trend, partly down to consumer demand. Lined with a grey synthetic satin with Milium.

Context: Milium fabric — a viscose rayon lining fabric woven with metallic thread for added insulation. Manufactured by Deering Milliken USA and advertised in Life magazine from 1950 onwards.

Labels/ Inscriptions: Woven label on internal breast pocket: ALEXANDRE Shape fast tailoring LINED WITH Milium.

Methods:

- Fibre manufacture: Extruded

- Yarn manufacture: Spun

- Fabric construction: Woven

- Garment Construction: Stitched

Material: Nylon (outer); viscose rayon (lining)

Measurements: Length centre back 76cm

Source: Unknown

Fake fur jacket of Courtelle™ acrylic and modacrylic, lined with acetate rayon with cotton pocket stabilisers

Object number: MoDiP: AIBDC 000261

Designer/Maker/Manufacturer/ Retailer: Unknown

Production country of the garment and components: Probably UK

Production date: 1960–80

Description: A short, lined, dark brown lustrous pile fabric (fake fur) jacket with long sleeves and two heavy plastic buttons with textured tops, front fastening, half belt and side pockets. The pile is densely threaded and gives the impression of pelts stitched together. The item requires specialist dry cleaning. The shortness of the jacket dates it on style grounds to the 1960s however there are signs it has been altered. It could have been cut down from a three-quarter length jacket, a style typical of the 1970s, making it an upcycled garment with an implication of two owners. These factors suggest that it was considered a luxury item.

Context: Polymeric fibres have been used to imitate fur since the late 1920s but technological improvements, together with the introduction of acrylic, provided a better-quality substitute from the mid-1950s. Pile fabrics typically consist of synthetic fibres pushed through a base fabric and melted into position.

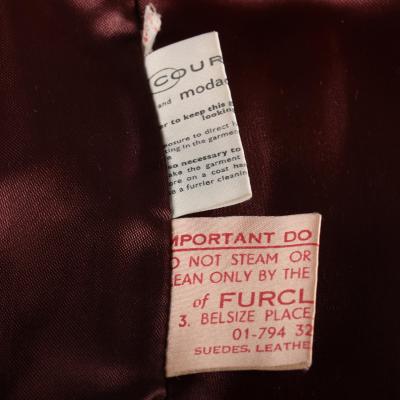

Labels/ Inscriptions: Two printed and one woven label sewn into a side seam (some lettering obscured by seam):

Label 1: COURTELLE ® and modacrylic pile. In order to keep this garment looking luxurious and elegant avoid *Exposure to direct heat * sitting in the garment and disturbing the pile. It is also necessary to * shake the garment * store on a coat hanger * use a furrier cleaning method when required.

Label 2: IMPORTANT DO NOT DRY CLEAN DO NOT STEAM OR HEAT THIS GARMENT CLEAN ONLY BY THE FURRIERIZED METHOD OF FURCLEAN LTD. 3, BELSIZE PLACE, LONDON, N.W.3. 01-794 3242 & 3243 SUEDES LEATHER & SHEEPSKINS.

Methods:

- Fibre manufacture: Farmed (cotton); extruded (acrylic and modacrylic)

- Yarn manufacture: Staple, spun (backing; lining); cut to length (imitation fur)

- Fabric construction: Woven (backing, lining); fibres embedded in woven backing (imitation fur)

- Garment Construction: Stitched

Material: Acrylic (Trade name: Courtelle) (backing); modacrylic (imitation fur); acetate rayon (lining); cotton (pocket stabilisers)

Measurements: Length centre back excluding collar: 72cm

Source: Gift

More information on this object: https://www.modip.ac.uk/artefact/aibdc-000261

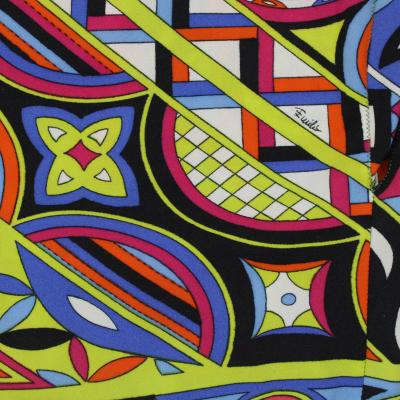

Emilio Pucci trousers of knitted nylon (polyamide)

Object number: V&A: T.585:2-1995

Designer/Maker/Manufacturer/ Retailer: Emilio Pucci (designer)

Production country of the garment and components: Italy

Production date: 1965

Description: A pair of form-fitting trousers in brightly coloured printed nylon (polyamide), complete with integral feet. Each leg is made from one pattern piece, joined at the centre front and shaped to the leg and backside with a seam along the centre back of each leg from ankle to waist. The leg pattern pieces stop above the ankle where the feet begin. Each foot is made with one pattern piece, sewn along the bottom of the foot from the toe up to the shin. The trousers have a separate waistband in the same fabric sewn on at the top, and a diamond-shaped gusset insert.

Context: Part of an ensemble with a silk shirt printed in the same pattern. The print was named ‘Dalia 1’. Throughout his career Emilio Pucci (1914–92) worked closely with several textile manufacturers to develop new textiles for clothing and improve dyeing techniques.

He was enthusiastic in adopting synthetics alongside silk. Here, nylon was likely chosen for its ability to maintain a form-fitting shape that would not sag or crease during wear.

Labels/ Inscriptions: EMILIO PUCCI/ FLORENCE – ITALY.

Methods:

- Fibre manufacture: Extruded

- Yarn manufacture: Twisted

- Fabric construction: Knitted

- Garment Construction: Stitched

Material: Nylon (polyamide)

Measurements: Unknown

Source: Given by Mrs Veronica Cohen

More information on this object: https://collections.vam.ac.uk/item/O351201/trouser-suit-pucci-emilio/

Ginger Group dress of woven viscose rayon

Object number: V&A: T.215-1987

Designer/Maker/Retailer: Mary Quant/Ginger Group (designer)

Production country of the garment and components: Britain

Production date: 1966

Description: A mini dress in a polo shirt style with contrasting collar and metal zip opening at the centre front, short sleeves and a welt pocket on each breast. The plain weave viscose rayon is quite rough feeling and has an appearance similar to linen, with some slubs.

Context: Mary Quant launched Ginger Group in 1963 as a lower-priced ready-to-wear range of fashionable womenswear. The linen-like viscose of this dress offered characteristics that would have been valued by the Ginger Group’s consumers. It was easy to wash and dry and would not crease — unlike natural linen — making it an easy to wear and easy to care for garment.

Labels/ Inscriptions: MARY QUANT’S ginger GROUP®/ MADE IN ENGLAND / 13

Methods:

- Fibre manufacture: Extruded, cut

- Yarn manufacture: Staple, spun

- Fabric construction: Woven

- Garment Construction: Stitched

Material: 100% viscose rayon

Measurements: Unknown

Source: Given by Mrs C. Archer

More information on this object: https://collections.vam.ac.uk/item/O365956/dress-quant-mary/

Jacket from a Burton man's suit of wool blended with Terylene™ polyester lined with viscose rayon

Object number: Leeds Museums and Galleries: LEEDM.S.1987.0011.4

Designer/Maker/Retailer: Burton (designer, manufacturer, and retailer)

Production country of the garment and components: UK

Production date: 1966

Description: Jacket from a man’s two-piece suit in a brown piece-dyed Glen check wool and Terylene blend. Jacket is single breasted fastening with three buttons. Factory order labels on inside of the pocket date the suit to 1966.

Context: The label shows that it is a made to measure suit. This is a more efficient method of production than a bespoke suit but is still more expensive than a ready-to-wear, off the peg suit. Burton was very much about making well-made suits for the ordinary man. For more about Burton and the benefits of using synthetic fibres please see number 11.

Terylene is the registered name for a polyester patented in Britain in 1941; commercially available for some products from October 1952. The FTIR analysis suggested the possibility of some nylon being included in the blend.

Labels/ Inscriptions: Woven label on internal breast pocket: BURTON tailoring wool BLENDED WITH ‘TERYLENE’

Methods:

- Fibre manufacture: Farmed (wool); extruded (polyester; cellulose acetate)

- Yarn manufacture: Spun

- Fabric construction: Woven

- Garment Construction: Stitched

Material: Wool blended with polyester (trade name: Terylene); viscose rayon

Measurements: Jacket chest 101cm

Source: Gift